태양광 챔버장비의 선두주자!

고객님께 최적의 솔루션을 제공합니다.

챔버 > 신뢰성챔버

챔버 > 신뢰성챔버

| Specification | NEC 110 | NEC Walk IN |

|---|---|---|

| Exposure Dimension (WxDxH in m) | 1.0x1.0x1.0 | User 사양협의 |

| Exposure Vol(in Liter) | 1000L | User 사양협의 |

| Temperature Operating Range | -50℃~+150℃(W/O Radiation) | -50℃~+150℃(W/O Radiation) |

| Ramp Rate (During Heating) | 2.0℃/min(단 -40℃까지 적용) | 1.7℃/min(단 -40℃까지 적용) |

| Ramp Rate (During Cooling) | 2.0℃/min(단 -40℃까지 적용) | 1.7℃/min(단 -40℃까지 적용) |

| Temperature Accuracy | ±1℃ | ±1℃ |

| Humidity Range and Accuracy | 30~95% RH | 30~95% RH |

| Cooling Mechanism | Air-cooled or Waer-cooled | Air-cooled or Waer-cooled |

| Door, Inner Chamber Material | Single type door, SUS 304 | Double wing or single type door, SUS 304 |

| Electric other voltage upon request | 380V±10%(3,N,PE)AC,50/60Hz | 380V±10%(3,N,PE)AC,50/60Hz |

| Physical Dimension(WxDxH in m) | 1.53mx1.55mx2.15m | User 사양협의 |

|

항온항습기는 소형부품, 대형부품, 반성품, 완성품등 온/습도 환경테스트를 제공합니다. |

| Specification | NTS-2ZL | NTS-2ZM | NTS-3Z | |

|---|---|---|---|---|

| Exposure Dimension (WxDxH in m) | 0.4x0.4x0.4 64L | 1.0x1.0x1.0 | 1.4x0.6x0.6 | |

| Test temp. range | Low temp. test | 30min | 30min | 30min |

| Hight temp. test | 30min | 30min | 30min | |

| Type | 2zone | 2zone | 3zone | |

| Low temp. test time | -70℃~-10℃ | -70℃~-10℃ | -70℃~-25℃ | |

| Hight temp. test time | 60℃~220℃ | 60℃~220℃ | 25℃~200℃ | |

| Test restoration time | -40℃~+85℃(5min) | -40℃~+85℃(5min) | -40℃~+85℃(5min) | |

| Cooling Mechanism | Air-cooled or Waer-cooled | Air-cooled or Waer-cooled | Air-cooled or Waer-cooled | |

| Door, Inner Chamber Material | Single type door, SUS 304 | Single type door, SUS 304 | Single type door, SUS 304 | |

| Electric other voltage upon request | 380V±10%(3,N,PE)AC,50/60Hz | 380V±10%(3,N,PE)AC,50/60Hz | 380V±10%(3,N,PE)AC,50/60Hz | |

| Temp. variation range | ±4℃ | ±4℃ | ±4℃ | |

| Temp. Uniformity | ±7℃ | ±7℃ | ±4℃ | |

| Physical Dimension(WxDxH in m) | 1.17m x 1.97m x 1.9m | 1.47m x 1.93m x 1.63m | 1.62m x 1.88m x 2.28m | |

| Standard | |

|---|---|

|

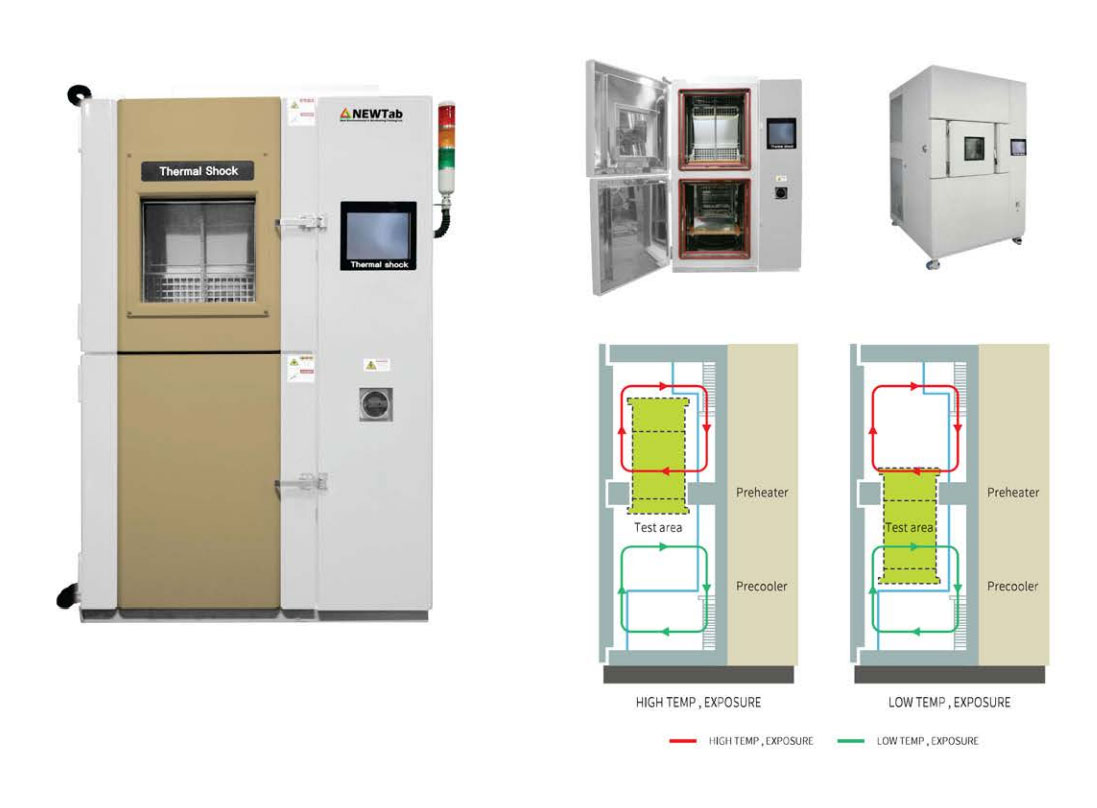

열충격시험에 요구되는 퍼포먼스에 더하여 온도 복귀 시간과 온도상승, 하강 시간의 단축, 소비 전력량의 저감, HFC 냉매, 소음의 저감, 공간 절약화 실현한 최고의 열충격 시험기입니다. |

| Specification | NCC-SALT | |

|---|---|---|

| Exposure Dimension (WxDxH in m) | 2.4 x 1.6 x 1.4 | |

| Exposure Vol(in Liter) | 5300L | |

| Temp.range | R.T ~ +60℃ | |

| Temp.accuracy | ±1℃ | |

| Temp.Uniformity | ±2℃ | |

| Salt Spray Method |

System | Air Pressure System, P.I.D ACTION |

| Spray Nozzle | 25~200 | |

| Salt Concentration | 5% PH 6.5~7.2 | |

| Mist Collection | 0~2.5ml/80c㎡/hour | |

| Door, Inner Chamber Material | Single type door, SUS 304 | |

| Electric other voltage upon request | 380V±10%(3,N,PE)AC,50/60Hz | |

| Exhaust vent | 내부 염분, Gas 배기용 Vent | |

| Nozzle Spary | 분사 압력 1.5kg/㎡ | |

| Physical Dimension(WxDxH in m) | 3.00m x 1.70m x 1.60m | |

|

염수분무시험은 도금 피막, 도장 피막이나 알루미늄 양극 산화 피막 등의 표면 처리와 스테인리스 소재 등의 재료의 내식성 평가를 위한 장치입니다. 소금물은 분무탑에 의하여 시험조 내에 균일하게 분무되기 때문에, 분산이 적은 시험을 할 수 있습니다. |

| Specification | NCC-AM | |

|---|---|---|

| Exposure Dimension (WxDxH in m) | 2.4 x 1.6 x 1.8 | |

| Exposure Vol(in Liter) | 5400L | |

| Temp.range | R.T ~ +50℃ | |

| Ammonia Exposure | 40±3℃, 667ppm 100% RFH(8hr) | |

| Spray Nozzle Device | 2set | |

| 1 test section |

Hours | 8 including heating up |

| NH3 - Concentration | 6,667 ppm | |

| Temperature | 60±3℃ | |

| rel. Humidity | Saturation at about 100% | |

| 2 test section |

Hours | 16 includingcooling |

| NH3 - Concentration | 0ppm | |

| Temperature | 18 to 28℃ | |

| rel. Humidity | max. 75% | |

| 암모니아 노출 | 40±3℃,667ppm 100% RFH(8hrz) | |

| Ambient 노출 | 23±5℃ 0ppm 75% RH(hr) | |

| Cabinet Size | 300±10L (750mm x 500mm x 800mm) W x D x H | |

| Ammonia+수증기배기 | 액체기준 배기랑 암모니아 4L/500hr 수증기 40L/500hr | |

| Ammonia 가스통 | 10kg | |

|

암모니아 시험 장비는 ISO 6988:1985(Metallic and other non organic coatings -- Sulfur dioxide test with general condensation of moisture)의 Test Conditions을 만족하는 장비로 장시간의 바본실험이 되므로 견고한 구조를 시험장비입니다. |

| Specification | NEPC |

|---|---|

| Exposure Dimension (WxDxH in m) | 2.5 x 1.8 x 1.8 |

| Exposure Vol(in Liter) | 8100L |

| Test temp.range | R.T℃ ~ 200℃ |

| Temp. & Humid range | ±0.2℃ |

| Temp. & Humid Uniformity | ±1℃ |

| Temp. heat up rate | RT ~ 200℃ heating : 4.0k/min |

| Temp. Pull down rate | 200℃ ~ RT Cooling : 1.0k/min |

| Accessories | Cable port : ¢50 x 1ea |

| Shelves : sts mesh type x 2set | |

| 카메라 투시장 (방탄유리적용) | |

| 화염커튼 설치 | |

| 소화자동 분사시스템 : HFC-23(청정약제) |

| UL 1642 | Standard for Lithium Batteries |

|---|---|

| UL 2054 | Household and Commercial Batteries |

| IEC 62133 | Safety requirements for portable sealed secondary cells |

| IEC 62660-2 | Secondary lithium-ion cells for the porpulsion of electric road vehicles - Part 2 : Reliability and abuse testing |

| SAE J2464 | Electric and Hybiid Electric Vehicle Rechargeable Energy Storage System (RESS) |

|

이차 전지는 모든 산업분야에 중요 해짐에 따라, 신뢰성 및 안전성이 매우 중요합니다. |